The role of plastics and polymer materials in controlling the corona virus

The 2019 coronavirus disease (Covid-19) pandemic is at its peak and the world is always fighting to help global public health. In this context, the role of polymers and polymer materials, including plastic, as the main material in medical equipment, personal protective equipment for health care workers is very high.

Advantages such as mass production, lower cost, and the ability to sterilize and disinfect plastic materials make them an inevitable material in the healthcare sector. Apart from plastic, antiviral and antimicrobial coatings, polymer nanocomposites and functional polymers have been introduced as aids against COVID-19. In recent years, due to the environmental pollution caused by the accumulation of plastics, countries have been looking for a way to eliminate plastics. The European Union, as the flagship of the fight against polymer waste, has been almost eliminating and reducing the use of plastics. Gloves and a group of masks were among these goods. But with the emergence of the Covid-19 virus and its epidemic becoming a global crisis, once again it was plastics that could be introduced as an effective factor in protecting personal health. This review focuses on the application of polymers and polymeric materials in the Covid-19 pandemic.

Use of plastics in hospital equipment

Due to the high rate of spread of this disease all over the world, the need for corona detection kits is important. Due to the wide spread of the disease, several times this number of kits are needed. Conducting any corona test as well as various medical diagnostic tests requires a number of sampling devices, vials, containers and plastic laboratory equipment. Therefore, the demand for these products has already increased hundreds of times. Blood and serum bags, various types of medical catheters, vascular flexible tubes, syringes, etc. can also be mentioned. These days, the manufacturers of these medical devices are on the front lines of the battle against Corona, along with the medical staff. All kinds of plastics including some goods and some engineering plastics such as low density polyethylene (LDPE), polypropylene (PP), polyvinyl chloride (PVC), nylon, polyethylene terephthalate (PET) and polycarbonate (PC) for Making different Personal Protective Equipment (PPE) are used. For example, in the past months, the transfer of plasma from recovered patients to infected patients has been identified as a factor in the treatment of this disease. This blood plasma is collected from recovered patients using the plasmapheresis process. Such membranes used for plasmapheresis are made of polyether sulfone (PES), polymethyl methacrylate (PMMA) or even PP.

Use of plastics in personal protective equipment

Plastic personal protective equipment is used to prevent the transmission of viruses and infections between people, the main and main of these equipments are face masks, gloves, face shields and medical gowns and bandages.

Global health concerns have always been to protect people from viral particles scattered in the air and to control it. Face masks are known as the most effective respiratory protective device. These masks can be very effective in preventing virus transmission. During the height of the corona virus, the use of respiratory masks is one of the preventive measures suggested to reduce the transmission rate of the corona virus, especially in asymptomatic and mildly symptomatic people.

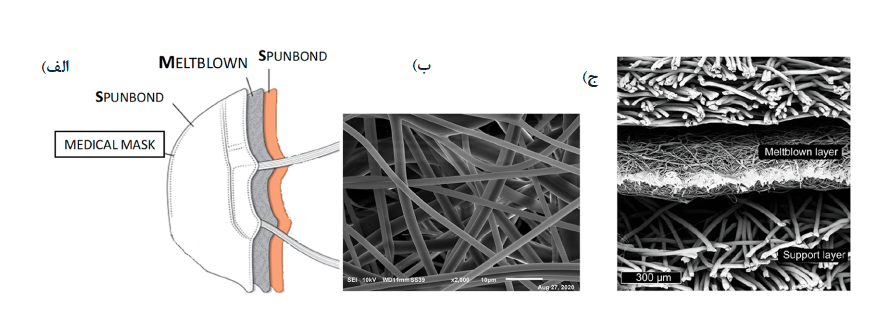

Face masks are various layers of non-woven fabrics made of polymer fibers, the main of which is composed of spunbond and melt blown balloons. In the Mellat Balloon production process, the machine uses high-speed hot air to draw out a thin stream of molten polymer that exits the mold opening, resulting in the formation of very fine fibers that condense on the plate or roller. These fibers become a non-woven fabric through "self-adhesion".

(a) Schematic view shows a medical mask, which consists of three layers, two spunbond layers and one inner meltblown layer. b) scanning electron microscope (SEM) images of the melting of the filtration layer and (c) and SEM images of the side view of the three layers of the mask

In order to facilitate the production of breathing masks and improve the conditions of the Corona epidemic, Rakhshan Plimer Sanat knowledge base company, using scientific support and through innovation, has started to produce Mellat Bloun compound for the production of Mellat Bloun fabrics.

Face shields, which are considered as protective equipment in environments infected with the corona virus, are made with thermoplastic polymers resistant to heat, impact and chemicals. Polycarbonate (PC) and poly(ethylene terephthalate) (PET) sheets are preferably used for this purpose because, in addition to their strength and unique properties, they can be produced with a high degree of transparency and are suitable for protective applications. They are ideal. For example, today, from PET bottles, using simple recycling processes, they can produce sheets of this polymer, which after completion, become face shields.

Polymer gloves are also among the most consumed products in the Corona era and these days we have seen the scarcity of this product in stores. Plastic gloves are divided into two categories: vinyl gloves (polyvinyl chloride) and polyethylene gloves. In addition to vinyl gloves, rubber gloves such as latex gloves have played an important role in controlling the corona virus.

Recycling of plastics used in the corona era

Plastics are considered a harmful pollutant due to their indiscriminate waste and mismanagement amidst the increase in plastic use and waste generation in this unprecedented crisis. Plastics, if properly managed and supplemented with circular economy strategies in terms of reduction, recycling and recovery, and thus preventing leakage into the environment, can save human lives and, in addition, greatly reduce energy consumption in the world. . The important point in using these plastics is that they should not be thrown away but should be selectively collected and recycled so that they are not left in the rivers, oceans and forests as a polluter of the environment. Used masks in hospitals may be considered hazardous waste. In this case, physical recycling, meaning extrusion in the molten state, can be considered as a safe way to dispose of waste, and instead of banning the use of plastics, they should be used responsibly in recycling, where it improves quality of life and if necessary to prevent the spread of infectious diseases, currently the corona virus.

Sources and references

- Gadhave, R. V., Vineeth, S. K., & Gadekar, P. T. (2020). Polymers and polymeric materials in covid-19 pandemic: A review. Open Journal of Polymer Chemistry, 10(03), 66.

- Armentano, I., Barbanera, M., Carota, E., Crognale, S., Marconi, M., Rossi, S., … & Calabro, G. (2021). Polymer materials for respiratory protection: processing, end use, and testing methods. ACS Applied Polymer Materials, 3(2), 531-548.

- Corrêa, H. L., & Corrêa, D. G. (2020). Polymer applications for medical care in the COVID-19 pandemic crisis: will we still speak ill of these materials?. Frontiers in Materials, 7, 283.

- Silva, A. L. P., Prata, J. C., Walker, T. R., Campos, D., Duarte, A. C., Soares, A. M., … & Rocha-Santos, T. (2020). Rethinking and optimising plastic waste management under COVID-19 pandemic: policy solutions based on redesign and reduction of single-use plastics and personal protective equipment. Science of the Total Environment, 742, 140565.